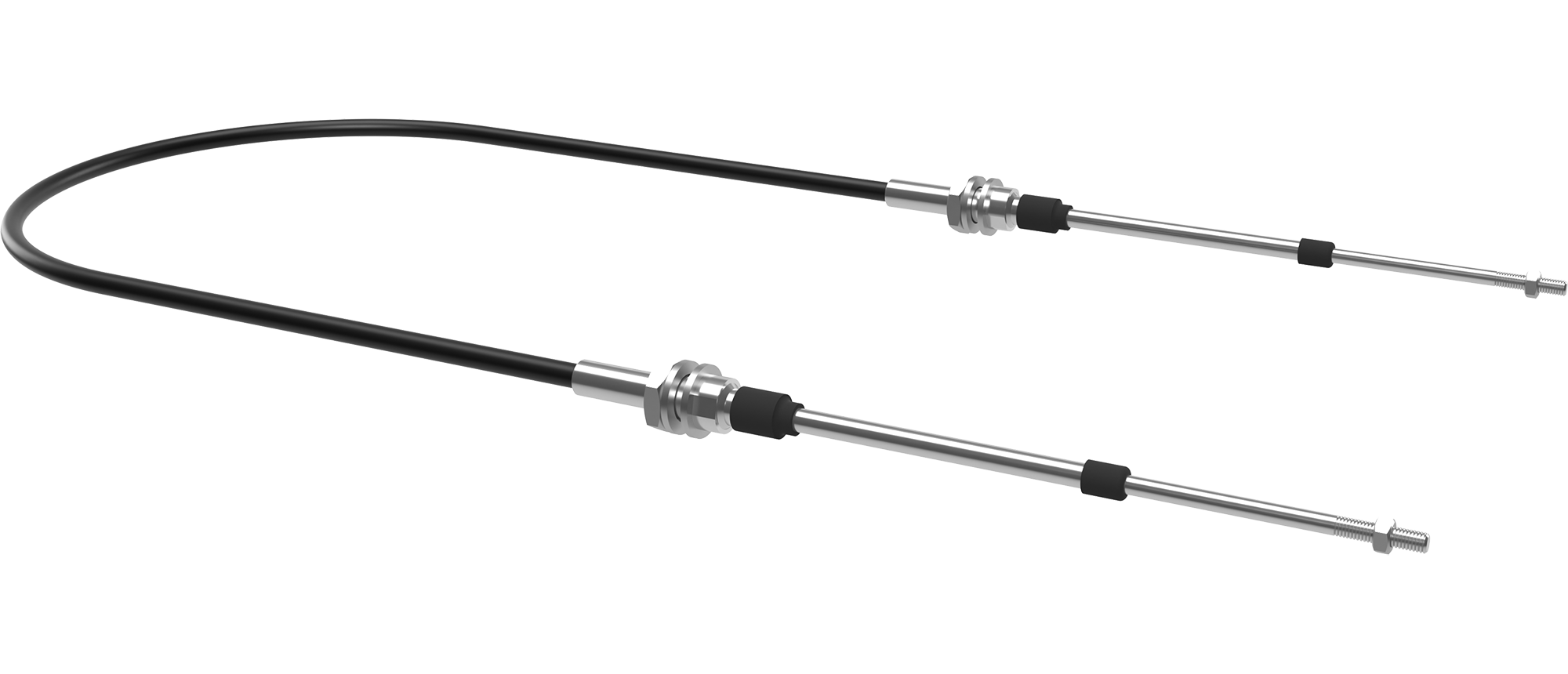

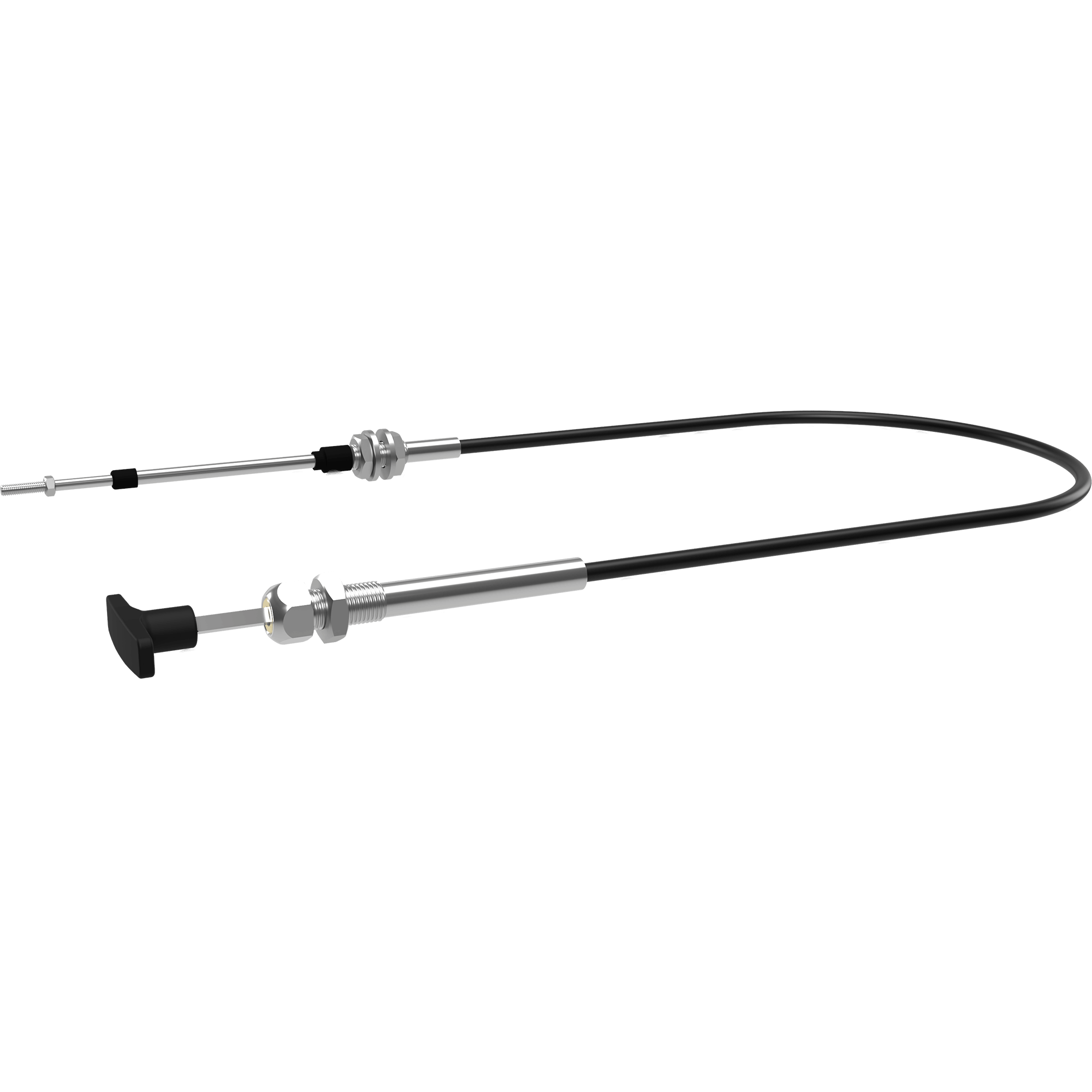

Push-Pull Cable

Fortatech Push-Pull Cable in the highest Swiss quality with excellent low-friction durable properties.

Bidirectional force transmission for demanding applications

Unlike conventional Bowden cables, push-pull cables can transmit forces in both directions - both pulling and pushing. This property makes them the ideal solution for applications where precise bidirectional movements must be realized through flexible paths.

With our high-quality push-pull cables, we offer you a reliable and durable solution for diverse applications in all industrial sectors. Thanks to the innovative OPALTECH technology, we guarantee highest performance with minimal operating forces throughout the entire lifespan.

Contact

OPALTECH – The innovative technology for your push-pull cables

Our OPALTECH technology revolutionizes the performance of push-pull cables through optimized friction properties and improved materials. In collaboration with the Institute for Materials Technology and Plastics Processing, we have developed a unique solution that significantly surpasses conventional systems.

Advantages of OPALTECH technology:

- Up to 10x longer lifespan – for sustainable and economical solutions

- Up to 3x lower operating forces – for better ergonomics and higher comfort

- Smooth operation – for optimized applications with low force requirements

- Friction-optimized – for consistent performance throughout the entire lifespan

- Grease-free – for clean applications and reduced maintenance effort

Structure and Function of Push-Pull Cables

A push-pull cable consists of a stable inner cable or rod that is guided in a flexible but axially fixed cable sheath. Unlike a simple Bowden cable, the inner element in push-pull cables is specially stabilized to transmit not only pulling but also pushing forces.

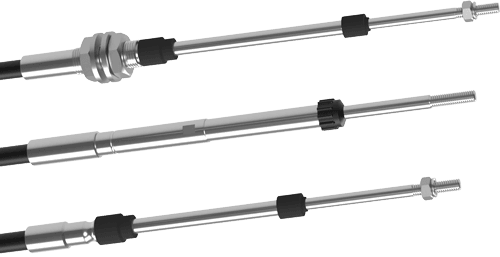

Components of a push-pull cable:

- Inner cable/Rod: Transmits both pulling and pushing forces, reinforced construction for pressure stability

- Cable sheath: Guides the inner element and provides stability, e.g. with special spiral hoses

- End pieces/Connections: Connection elements to the components to be moved, individually adaptable

- Special guide elements: Guarantee precise guidance of the inner element even under pressure load

The careful coordination of all components guarantees optimal function even with complex routing paths. The correct dimensioning of the push-pull cable depends on the force to be transmitted, the routing path, and the environmental conditions.

Detailed structure of a push-pull cable with components

Application Areas for Push-Pull Cables

Our high-quality push-pull cables are used in various industries and applications, wherever precise bidirectional force transmission is required. Through our decades of experience, we can offer the optimal solution for every application case.

Industry and Mechanical Engineering

Machine and plant construction

Actuators in process automation

Control elements in machine tools

Valve actuations in fluid technology

Lifting units in conveyor technology

Positioning tasks in medical technology

Locking systems in safety devices

Remote controls in marine and offshore technology

Control components in aviation technology

Automation technology

Automotive and Vehicle Technology

Shifting and selection systems for transmissions

Unlocking systems for hoods and tailgates

Adjustment units for seats and steering wheels

Operation of flap controls

Engine controls in commercial vehicles

Actuators in agricultural machinery technology

Controls in rail vehicles

Marine and shipbuilding

Renewable energies

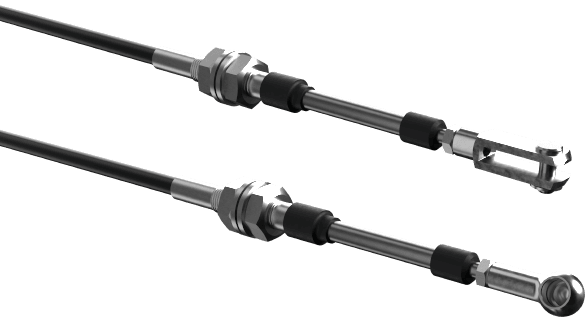

Our Push-Pull Cable Product Lines

We offer two main product lines of push-pull cables that differ in their sheath diameter. The OPALTECH 7 series with 7mm diameter for more delicate applications and the OPALTECH 11 series with 11mm diameter for higher loads. Each series includes various variants for different requirements.

OPALTECH 7 Series (7mm sheath diameter)

The compact series for precise applications with medium loads.

Maximum tensile load: 600 N

Maximum compression load: 280 N

Minimum bending radius: 100 mm

Temperature resistance: -40°C to +80°C

OPALTECH 11 Series (11mm sheath diameter)

The robust series for demanding applications with higher loads.

Maximum tensile load: 1300 N

Maximum compression load: 650 N

Minimum bending radius: 150 mm

Temperature resistance: -40°C to +80°C

Our Product Number System - Simply Explained

The designations of our push-pull cables follow a logical system that helps you with selection:

OPALTECH 11.4-100

11 = Sheath diameter in mm

The larger, the stiffer and higher the load capacity

4 = Variant

Different designs for various applications

100 = Stroke in mm

The possible movement length of the push-pull cable

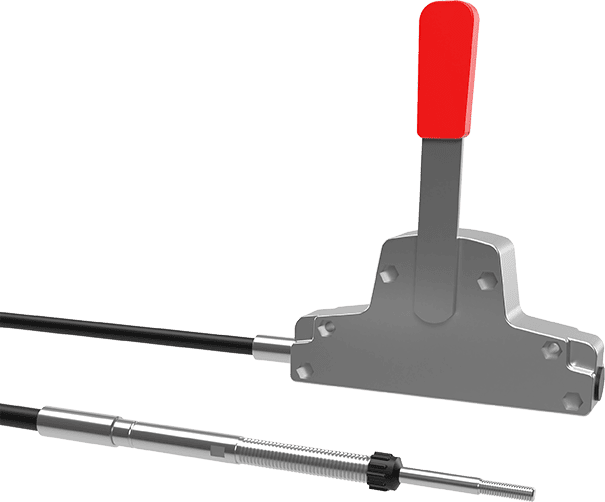

New: OPALTECH 7.4 with innovative 90-degree fixation

Our latest product in the OPALTECH family offers a groundbreaking function for even more flexibility and precision in your applications.

Unique advantages:

Precise 90-degree movement for targeted positioning

Secure fixation in any position through the innovative T-handle

Variable application possibilities thanks to flexible positioning

Easy operation through ergonomically designed T-handle

All OPALTECH advantages such as low friction and long lifespan

This innovative function enables even more flexible application and increases precision and safety in your projects.

Push-Pull Cables vs. Bowden Cables - The Right Choice for Your Application

Push-Pull Cables

Force transmission in both directions - both pull and push

Ideal for precise positioning and controlled bidirectional movements

Specially reinforced inner core for pressure stability

Higher precision through defined movements in both directions

Fewer components in the overall system due to bidirectional function

Easier integration into complex systems

Recommended for: Applications requiring precise bidirectional movements, such as positioning systems, locks, controls and adjustment mechanisms.

Bowden Cables

Force transmission only in pulling direction - no pressure transmission

Simpler construction and often more cost-effective

More flexible routing for complex paths

Lower weight due to simpler construction

Smaller minimum bending radii possible

Ideal for simple actuations and longer transmission paths

Recommended for: Applications requiring only pulling forces, such as release mechanisms, unlocking, simple switching operations and applications with limited installation space.

Unsure which solution is right for your application? Our experts are happy to advise you!

Request consultation